Sulfur Removal & Recovery

| Technology Overview | Flow Diagram | Project Case |

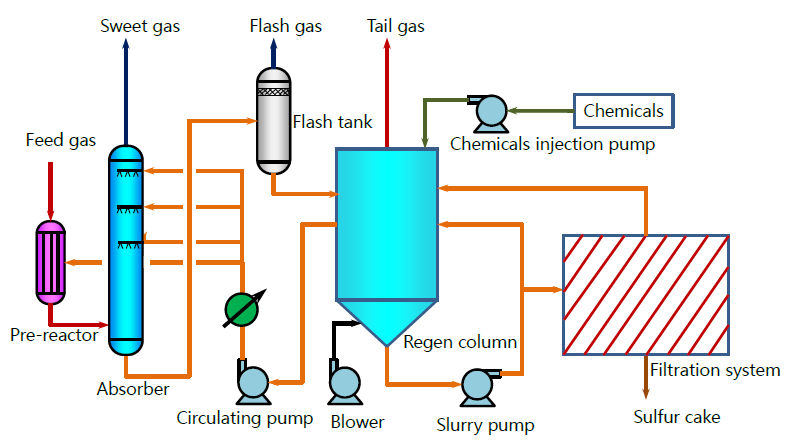

Liquid phase oxidation process for sulfur removal utilizes complex iron ions as the catalyst, hydrogen sulfide dissolves in the solution when feed gas and catalyst solution contact each other. Hydrogen sulfide-rich solution is regenerated by air entering the oxidation tower. By circulation, hydrogen sulfide will be oxidized to sulfur, and to become a filter cake through filtration. This technology can also adopt self-circulation way, combining absorption column and oxidation column, so absorption and regeneration can happen at the same time.

Technical Characteristics:

Integration of sulfur removal and recovery

Low investment

Low energy consumption

Nontoxic and harmless catalyst

High efficiency in organic sulfur removal

No discharge of liquid waste

Device characteristics:

Skid-mounted device available for below 10t/d scale; modular device available for 10t/d to 30t/d scale.

Working Conditions and Application Areas

Applicable scale for a single device: 0.5t/d~30t/d

Purity of product gas(H2S content): as low as 1ppm

Applicable gas source pressure: atmospheric pressure~30MPaG

Applicable gas temperature: 0~60℃

Application Areas:

Sulfur removal for natural gas and associated gas

Sulfur removal for sour tail gas and sulfur recovery

Sulfur removal for Claus device tail gas

Sulfur removal for refinery gas

Sulfur removal for coke oven gas

Sulfur removal for biomass gas

Sulfur removal for syngas