RECIRCULATING COOLING WATER SYSTEM FOR LARGE-TEMPERATURE-DIFFERENCE SERVICE

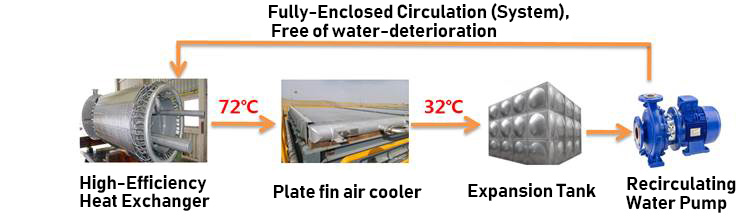

1. High-efficiency heat exchanger (spiral wounded type or twisted tube type) is adopted to replace shell & tube heat exchanger to decrease temperature difference during heat transmission, in this way, temperature on returning water will be raised up to 70℃~80℃;

2. The system doesn’t adopt water-cooling tower. Instead, plate-fin condenser is used to perform function of cooling to bring temperature of recirculating water down to 30℃~35℃;

3. The system can lower down investment on the equipment and decrease energy consumption for its recirculating water-flow is about 20%~30% of other conventional cooling system when running at a same cooling load.

4. This system can save over 70% of energy consumption comparing with conventional indirect air-cooling counterparts, and over 20% rather than water-cooling tower system.

5. A fully-enclosed circulation to keep recirculating water out of deterioration and achieve zero consumption of raw water and zero discharge of waste water.